LKV Series

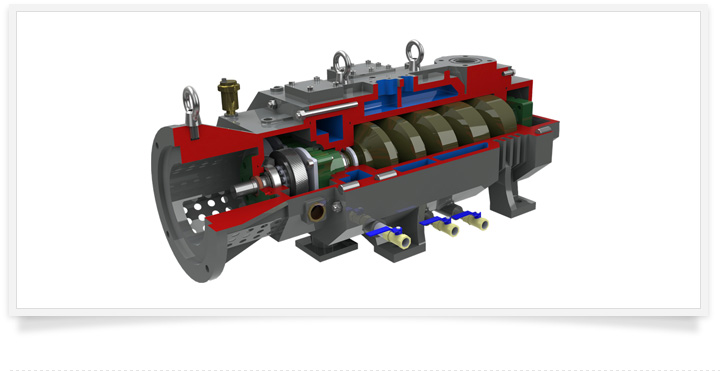

Structural Overview

| 1 | Suction |

|---|---|

| 2 | Discharge |

| 3 | Screw |

| 4 | Casing |

| 5 | Seals |

| 6 | Bearings |

| 7 | Timing Gears |

| 8 | Shaft |

| 9 | Cooling Water Jacket |

Characteristics

Excellent discharge performance

- Superior liquid handling ability

- Self draining mechanism

- Excellent dust handling

- Quick exhaust structure

- Pulsation reduction of gas emission

Oil Lubrication

- Applied oil lubrication type of Rear End Plate(REP)

Reliable seal structure

- Triple Sealing System with Lip seal + Gas Purge + Mechanical Seal

- High performance mechanical seal specifically designed for dry vacuum pump

- Optimum gas purge operation enhanced leak tightness

Gas ballast nozzle installation

- Prevent condensation of corrosive vapor

- Reducing explosive atmosphere

Advantages

Ultimate Vacuum

- Optimized clearance and continuous compression ensures 0.0075torr vacuum degree with a single pump

Corrosion Resistance

- Coating material provides excellent corrosion resistance

- Process specific coatings or platings available

- Enhanced Corrosion Resistance by the gas ballast

Cooling Effect

- Hydrodynamic spiral jacket design ensures Excellent heat exchange efficiency

- Maintains optimum pump-inside temperature

Utility Saving

- 30% power saving by the variable pitch

screw design - No extra cooling gas required

Benefits

- No Contamination of Process Stream

- Deeper Vacuum and More Flexible Operation

- No Effluent, No Pollution, No Waste Disposal Costs

- Lower Maintenance Costs

- Immediate Solvent Recovery at Pump Exhaust

- Lower Total Cost of Ownership - Lower Utility Costs

- No variation in vacuum resulting from the changing of seasons and Utility

Technical Data

| Model | LKV300 | LKV400 | LKV800 | |

|---|---|---|---|---|

| Displacement(50/60Hz) | m3/hr | 250/300 | 330/400 | 660/800 |

| Ultimate pressure | ||||

| without Gas Ballast | torr | 7.5 X 10-3 | 7.5 X 10-3 | 7.5 X 10-3 |

| with Gas Ballast | torr | 0.01 | 0.01 | 0.01 |

| Motor power(50/60Hz) | ||||

| Power Requirement | kW | 7.5 | 11 | 15 |

| Power Consumption | kW | 5.0/6.0 | 7.0/8.6 | 10.2/12.8 |

| Rotation(50Hz/60Hz) | rpm | 2,900/3,500 | 2,900/3,500 | 2,900/3,500 |

| Process Connection | ||||

| Inlet Connection | JIS(ASME) | 50A(2”) | 65A(2 ½”) | 100A(4”) |

| Outlet Connection | JIS(ASME) | 40A(1 ½”) | 50A(2”) | 65A(2 ½”) |

| Cooling water | ||||

| Max. Supply Pressure | Barg | 7 | 7 | 7 |

| Pressure Drop | Bar | 1 | 1 | 1 |

| Flow Rate | Liter/min | 10~15 | 10~15 | 15~20 |

| Temperature | ℃ | 5~35 | 5~35 | 5~35 |

| Connection | PT(JIS) | ½”(15A) | ½”(15A) | ½”(15A) |

| Lubricant | ||||

| Gear Oil Type | Shell T-68 | Shell T-68 | Shell T-68 | |

| Bearing Oil Type | Shell T-68 | Shell T-68 | Shell T-68 | |

| Seal Type | ||||

| High Vacuum(HV) Seal | Lip Seals(Double Lip Seal x 2ea) or Mechanical Seal | |||

| Low Vacuum(LV) Seal | Lip Seal & Mechanical Seal(or Lip Seal) + Gas Purge Seal | |||

| Noise Level(50/60Hz) | dB | 79/85 | 79/85 | 79/85 |

| Vibration (max.) | mm/s | 1.8 (4.5) | 1.8 (4.5) | 2.8 (4.5) |

| Weight(Bare Shaft) | kg | 300 | 380 | 600 |

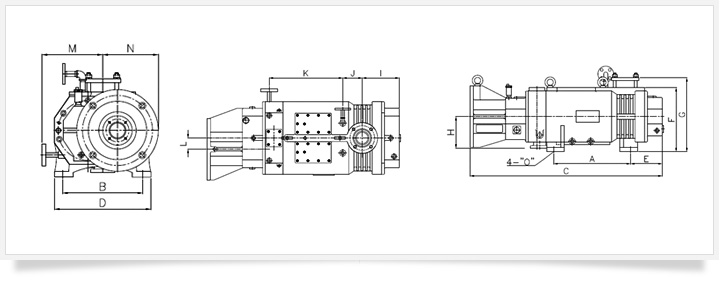

Dimensions

Bare Shaft Dimensions

| Model No. | LKV300 | LKV400 | LKV800 |

|---|---|---|---|

| A | 395 | 437 | 558 |

| B | 334 | 344 | 380 |

| C | 985 | 1100 | 1263 |

| D | 398 | 414 | 482 |

| E | 164 | 180 | 185 |

| F | 354 | 365 | 420 |

| G | 410 | 421 | 505 |

| H | 183 | 180 | 208 |

| I | 193 | 211 | 240 |

| J | 117 | 111 | 145 |

| K | 319 | 419 | 458 |

| L | 58 | 63.5 | 73 |

| M | 260 | 260 | 278 |

| N | 208 | 239 | 248 |

| M | 19 | 19 | 22 |

| Weight | 300 | 380 | 600 |

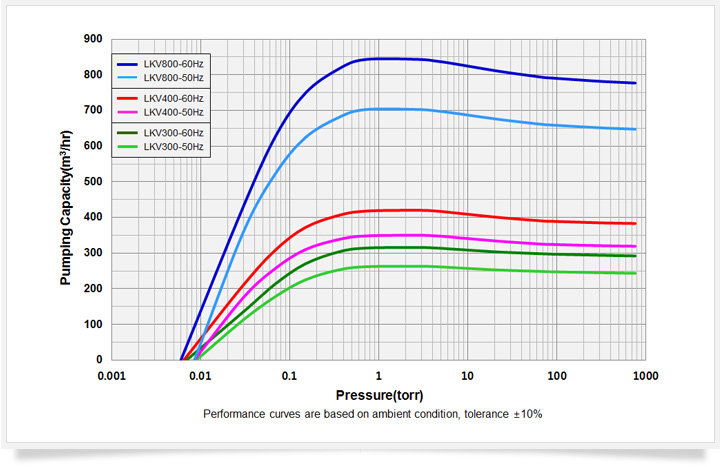

Pumping Capacity